Comments

-

"our system needs service"It was not unusual to connect to a footing drain where it day lighted in the early 90s.

Typically a PVC T was installed so the fan could be mounted vertically and a 4" check valve was installed downstream of the T. I attended certification class in 1990 that demonstrated that type of system on the field trip. The enclosure was a little more professional. -

California's New Interactive Radon MapThe EPA map, created in 1993 and that I don't believe has changed since I started in 1990, clearly shows western South Dakota as zones 2 or 3. There is nothing on that map that tells a new viewer what those numbers mean and maybe that is a good thing since the area is not low to moderate. Western SD is the home to historic and current uranium mining. I have seen levels above 1,000 pCi/l and urban areas where every home is triple digits.

Experienced builders install active systems during construction because they have had sales fall through when a high test comes in not because they looked at the EPA map.

I helped a home owner attempt to mitigate his home that was above 500 pCi/l. The owner was going to install a passive system during construction but changed his mind when he looked at the EPA map. He has got it down below 10 and has decided to live with that since the next steps are both expensive and unattractive.

The USGS maps clearly show the risk is high and 30 years of testing have proved that fact yet the EPA map remains unchanged and inaccurate. It should be removed from the website. I believe people looking at the map use it as a reason for inaction. Even if it was updated to perfectly match the USGS maps it would not accurately reflect the surface geology that can vary from lot to lot in a subdivision.

https://www.epa.gov/sites/default/files/2015-07/documents/zonemapcolor.pdf -

House from Heck

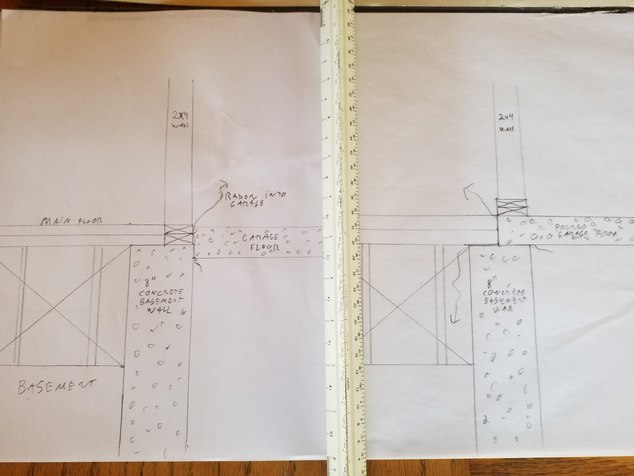

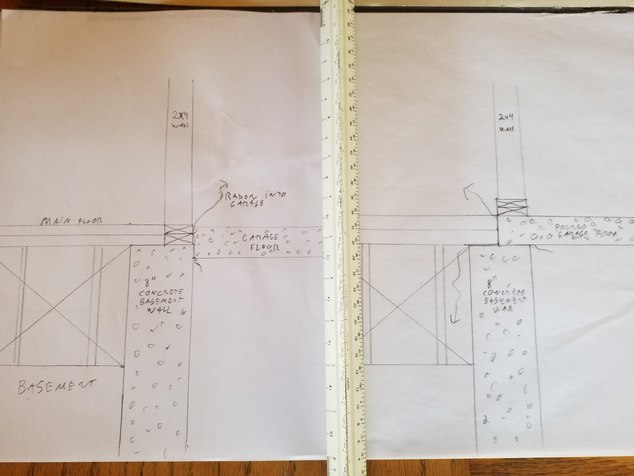

On the left. In our area when the owner does not want steps from the garage to the main level hanging trusses are used and typically the garage floor is poured against the basement concrete wall and the interior walls are constructed on top of the concrete basement wall. Any radon coming from under the garage floor enters the garage where it is usually not contributing to the interior house level. The drawing on the right shows the garage floor poured on top of the basement wall and the interior walls constructed on top of the garage floor which allows radon to flow into both the basement and upper level.

I was fortunate that the basement utility room was unfinished and I could see the garage floor sitting on top of the basement wall.

Bob -

House from HeckIs there n attached garage? We had a home that had a draintile installed under the basement floor so we had suction everywhere but the radon level would not go below 10 pCi/l. The garage slab was poured level with the main floor level but instead of butting up against the basement walls as is typical it was poured on top of them. The basement utility room was unfinished so I was able to place a CRM on top of the poured basement wall adjacent to the garage slab. The level was 150 pCi/l.

A second suction point in the garage connected in the attic to the system we already installed solved the problem. -

House from HeckYou seem unsure about the exterior basement walls. Could they be block and not poured concrete?

-

Alarms are mandatory now on radon systems9.3 Fan Location

In the early days of radon mitigation, prior to development of the US mitigation Standards, the fans used were not airtight, and leaked some of the exhaust air from their casings. A variety of ducting materials was also used and not all joints were airtight. As a result, best practice was to place the fan and discharge piping outside the building envelope. The interior piping was then under negative pressure, so neither fan nor duct leakage would enter the building. Fans located outside the building envelope are required by US mitigation standards.

In-line centrifugal fans specifically designed for radon mitigation are now available. Some airtight fan designs are available with sealed joints; some have the casing joints and electrical connections located on the suction side of the fan, so leakage from the fan is not a concern. Plastic plumbing pipe is now used routinely for the suction and exhaust ducting, with airtight solvent welded joints in the piping and airtight rubber plumbing couplers to the fan.

As properly installed fans and ducting will not leak soil air and radon into the building, the fan no longer needs to be located outside the building envelope, but can be mounted inside the building. If this is combined with a grade level discharge, almost the entire system can be inside the thermal

envelope. In cold climates, this eliminates concerns about condensation or frost in the fan or piping, as only a short length of discharge pipe outside the house will be exposed to colder temperatures.

Canada has kept up with the science. Perhaps we need to look to them for solutions to problems we have created. -

Alarms are mandatory now on radon systemsThe larger one looks perfect. Right now I found UV protected tackle boxes for around $20. This issue only comes up for me with horizontally drilled systems on the outside. I have run PVC conduit with tubing in it down the wall to a place where we could go into a house and mount a manometer. It is rare to have that option.

I can see a time in the future when a CRM, mounted on a basement wall, is almost as common as smoke detectors. It may be helpful for the standards committee to think about guidelines for a CRM that serves as the system monitor. Accuracy, audible alarm with a delay, 5 year warrenty, ac power + battery backup, reasonable cost for factory recalibration or exchange.

This would address the the issues of outside systems, false alarms, testing radon every two years and would give homeowners a clear understanding of what the monitor is telling them. I have homeowners that think that as long as the red fluid is below 4 they are fine.

As CRMs come down in cost they are becoming more attractive for this solution. -

Alarms are mandatory now on radon systemsVery good discussions. Re-entry through the sill seal can easily be observed with a smoke gun in older homes but new homes in our area usually have the band joist spray foamed. I always felt that venting adjacent to the kids sandbox or what could be a frequently used outdoor area was another reason for venting 10 feet above the ground.

I have been told that at 3' or more beyond the vent, radon is typically at average outdoor levels. Is there research on that?

The actions and attitudes of the public are varied and unpredictable. I have one client that has two CRMs and sends me a text msg every morning with the results. His aim is to never have the level go above 4 pCi/l no matter what the weather is. Drilling a 3rd penetration and installing a 4th Rn4 seems to have done the trick. If a freeze up occurs this winter I'm sure he will want some sort of defrosting heater installed. Cost and noise is not an issue for him.

His neighbor has a level above 200 and has delayed putting in a system for 2 years so far.

Audible alarms may be fine in some areas but not in others. Getting the best science and reasoning behind the standards and perhaps listing some things as options instead of mandatory is the answer. -

Alarms are mandatory now on radon systemsI've considered the 0-5 minihelics but I was a little worried about labeling that would explain its message through changes in ownership and not fade over the years. Following Wally's photos led me indirectly to a different weather proof tackle box that is solid on the back and sides but has a clear plastic lid that is

treated to protect itself and whatever is in the box from UV. If you have a photo of a minihelic installation or suggestion for better labeling my email is radonatearthorizonsdotcom.

The Canadian solution certainly has merit for solving the labeling, freeze up and astetic issue. I know there were good reasons for putting fans outside in the 1990s when fans were screwed together and spewed radon out the seams. That is no longer true and perhaps it is time to revisit those standards. -

Alarms are mandatory now on radon systemsWally,

Thanks for the reply. I've found the best information often comes from other professionals and not the CE courses. I started using tackle boxes 3 years ago but the ones I used tend to get brittle and fall apart

In the sunlight. I have calls to replace two right now. I'll check out the links you sent to see if there is a better choice. It would be nice to continue to use clear ones but maybe that isn't possible with UV protection.

I'll bore you with another freeze up story. I installed an exterior system on a walk out basement and used the plumbing opening in the slab under the basement bathroom tub as our suction point. It was about 12" by 12" wide, almost as deep and right next to the exterior wall. I did my typical process of placing a 4" pipe in the void, filling it with clean gravel up to the bottom of the slab and sealing the top with spray foam.

A couple of years latter the new homeowner called because the tub wasn't draining and thought it had something to do with the radon system. They had unplugged the fan. I concluded that with the fan off cold air was going down the pipe and under the tub next to the P trap. I activated the system again and talked to them about my suspicion and the danger of radon. They called the next day to let me know the tub was draining.

I usually just seal these plumbing penetrations but it's location was adjacent to the only location we could drill. I neve suspected it could result in a frozen P trap until it happened.

Thanks for the advice. I'll check those links out. -

Alarms are mandatory now on radon systemsWally,

Just last year I had a system entirely inside freeze up. There was a blizzard in the Northern Black Hills durring which the power was out for a short time. The fan was in the attic and froze when it was not running.

Two days after the storm the homeowner called me because the manometer was at zero. I asked if the power had gone off and he said no. I drove over 100 miles the next day to check it out and everything was working fine. The wife confirmed my suspicion that the power had gone off for a short time durring the storm.

Audible alarms were popular in 1989 when I first started but lost favor because of the false alarms.

Low cost continuous monitors have become very popular for homeowners in my area and I had to use one in a home that had no suitable location for a manometer. That one resulted in a call back 3 years later when the homeowners visiting son unplugged the fan. The monitor did its job.

I have considered using a monitor on houses that have the entire system outside and there is no way to mount a manometer inside. I have found no suitable enclosure to protect it from the elements . The labels fade, the red fluid turns clear. Any solutions to that problem out there? -

Sealed poly in Passive Crawlspace SystemSome builders in our area install unsealed plastic in the crawlspace and then cover it with gravel. Often there is draintile under the plastic leading to a sump pit. We have had great success in reducing the radon by connecting our system to the sump pit or drain tile. The only sealing we do is around the sump.

The gravel on top pushes the plastic against the foundation and creates an lmperfect but adequate seal. -

I have 2 questions.Great advice from everyone. Several years ago I ordered a crawlspace sump pit which is shorter that the typical pit used in our area. It came with a lid that had a hole for the electrical cord or cords and a rubber grommet for that hole. It also had two 3 1/2" holes with a variety of rubber seals for 1 1/4 through 2 " pipe plus two solid rubber seals to be used if there was no pump installed. I discovered this was a perfect replacement in existing sump pits that had an open slot or other non airtight lids. We drill a 4 1/2" hole for the radon pipe. We clean the lip on the sump pit where the lid sits and apply weather stripping to it for the airtight seal. Often smoke tests show no leaks but we usually screw the lid down with 4 small deck or stainless steel screws. Occasionally silicon caulk is needed to help seal the perimeter but usually the weather stripping is all that is needed which makes it easily removable.

We put the second 3 1/2" rubber seal in the hole that isn't needed for the sump pump pipe. This seal easily pops in and out and serves as an inspection hole and access to reach in and manipulate the float or use a shop vac to clean sediment.

I don't want to push a particular supplier or manufacture on this site and the supplier I get them from does not list the lids separately from the pits. They special order the lids dropped shipped from the factory to me. -

I have 2 questions.George, can you put the fan in the garage attic or is their living space above the garage? If the garage attic is conditioned you could build your fan closet in the attic without taking room out of the garage.

We have convinced many builders in our area to put a "T" in the draintile pipe before it enters the sump pit. A 4" PVC DWV pipe is extended through the floor for future radon use if needed. You still need a sealed lid for the sump pit but having the radon pipe seperate makes it a little easier to work on the sump pump.

Also that pipe can be extended through the floor anywhere and you may have ia location that makes more sense for the radon piping than where the sump pit is located.

About 60% of our mitigations go from a sump pit, into the garage and up through the garage attic and roof with the fan in the attic. I would suggest using 4"pipe for everything. We have had to abandon some plumber installed systems that used 3" pipe because we could not move enough air no matter what fan or combination of fans we tried. -

reasons for mounting the fan and exhaust piping outside building envelope in USWhen I first started in 1989 fans were leaky and people were using dryer vent tubing with the vent out of the side of the house into the children's sandbox. The fan placement, pipe material and venting protacals developed in the 90s made sense. However fan construction has improved and studies in Canada indicate venting at ground level dose not result in elevated levels in the house.

Venting protacals still make sense in new construction but can be a challenge with existing homes.

Fan placement outside the conditioned space can raise the cost, because of the need for an electrical outlet, and creates fan issues because of extremely cold or hot locations. Astetics is also an issue. One builder asked why don't we put the toilets outside because the waste pipes may leak.

Another collateral damage issue is that certified mitigators lose business because builders and homeowners turn to someone who will install in the basement or crawlspace when there are no local building codes stating otherwise. -

I have 2 questions.Larainne,

You brought up a very good point that maps can be an excuse to downplay the risk and an excuse for inaction. This is especially true for municipal governments that are under pressure to not add to the regulations. When the USGS map clearly shows it is at high radon risk geologicaly and the EPA map says the opposite, but is supposed to be based in part on geology, it raises questions on the accuracy of EPA information in general. I have had conversations with personnel in the Rapid City code inforcement that believe radon is a hoax. I can slowly get their minds changed but the map is a weapon used by homebuilders to resist new regulations. -

I have 2 questions.I agree with Ed but George brought up a topic that has bothered me for years.

The outdated and inaccurate EPA Radon risk map. I live and mitigate in the Black Hills in western South Dakota. The EPA map shows this area as 2 where radon levels are expected to be below 4 pCi/l. Uranium mining and exploration has been occurring here since the 1940s. The largest population centers are all in the uranium bearing formations that surround the Black Hills. We see neighborhoods where all the homes are in triple didgets, some above 500 pCi/l. In the central hills, well away from those formations, levels above 1,000 have been seen.

The USGS radon map clearly shows this risk area yet, with all the testing since 1993, the EPA map has not changed.

The EPA should at least update their map with the USGA data. Better yet they should incorporate data from radon testing over the quarter century of testing that has occurred since 1993. Homeowners and local government agencies look at that map and use it to make decisions about testing, radon resistant construction and building ordences. -

Time Magazine misses the radon storyAmazing. Is it possible women spend more time in homes with elevated radon levels? Or how is it possible that that thought didn't occur to anyone researching this.

-

Anyone heard of these folks?The scary part is that they would be proud enough to take photos and release them to the public

Robert Burns

Start FollowingSend a Message

- Terms of Service

- Useful Hints and Tips

- Sign In

- © 2026 Radon ListServ