-

Robert Mahoney

44With respect to re entry, I did have it occurr once, in a very low cfm system, a simple 4 to 2 1/2 bushing, increased the velocity enough, to solve the issue.

Robert Mahoney

44With respect to re entry, I did have it occurr once, in a very low cfm system, a simple 4 to 2 1/2 bushing, increased the velocity enough, to solve the issue. -

Marcel Brascoupe

9For the first 200 systems installed that I was involved with here in Canada, we installed audible alarms on ALL of them.... of the 200 systems that had alarms, I have replaced at least a dozen in the first 5 years where the power supplies stop working, probably because of the frequent power outages we get here in my region. Probably gets zapped with a power surge when the power comes back on...

Marcel Brascoupe

9For the first 200 systems installed that I was involved with here in Canada, we installed audible alarms on ALL of them.... of the 200 systems that had alarms, I have replaced at least a dozen in the first 5 years where the power supplies stop working, probably because of the frequent power outages we get here in my region. Probably gets zapped with a power surge when the power comes back on...

Only way the occupants noticed that they were not working was that they noticed that the lights on the alarm were not lit up green or red anymore.... no lights period to show that the alarms were still operational.... I wonder how many more units might be out of commission because of defective power supplies and the homeowners don't know that they are not working because they have not checked to see if the lights on the alarm are lit up.... they may think that everything is ok but in reality, they are not operational anymore... I guess we get back to the "U" tube manometer debate again... how many homeowners really check them regularly ? No perfect solutions I guess... -

Andrew Costigan

34Thanks for sharing that Marcel.

Andrew Costigan

34Thanks for sharing that Marcel.

This goes to show how important field testing is prior to requirement of such a major change to a radon mitigation system. If required - there needs to be a standard on the make-up of that individual piece of required equipment to protect “us” the mitigation contractors installing them. Fail-safes - what happens when the alarm fails - is there a beep to let the homeowner know? What is the warranty on these alarms? Is it the same as the typical 5 year warranty on the fan? If alarms have a shorter life then the fan - will anyone voluntarily replace them?

If homeowners think an alarm or light will tell them about a dead fan and the alarm is dead then they will have a false sense of security and never check the fan. How about the cost $ on the mitigator? How much would a service call need to be for a mitigation contractor to replace a dead alarm or dead battery. This leads us back to what the manufacturers warranty is on the alarm. Needs to match the fan warranty? Hopefully all this was thought about by the SGM-SF consensus body members. -

Brian Geswein

16Indeed, there is no perfect solution. A silent alarm is no better than the manometer, and I think we can all see issues with the audible alarm. At some point I think you have to put some of the responsibility of maintaining checking the system on the homeowner. I'm thinking more of this time being spent on alarms, etc. should be put into educating the general public. If they don't understand what the radon mitigation system is then no matter what you supply them with will not matter. Personally, I think the manometer, as all manufactures produce them, are one of the most misunderstood pieces of the radon mitigation system. Most say "system monitor" on them, and then there are numbers 1-4 printed on it. To many, outside the radon industry, that little devise is showing radon "level". I know the label right next to it says it is not radon level. BUT, who reads labels! All much of the general public know about radon is it should be under 4, (In the US) and this little "monitor" clearly shows the "level" is below 4. ALL IS GOOD!! I think the word monitor should be removed as well as the numbers. Leave only the lines as they are. When I brought this up to a major manufacturer a few years ago they said the numbers where there for mitigators to know the pressure. In my opinion any competent mitigator could figure that out without having the number printed on it. The only way to determine if a radon system is "working" is to test. There are many "running" systems out there that are not working. I know some mitigators leave monitors for homeowners to use. That is fine until the homeowner moves and takes it with them, or lends it to someone else to use and it never comes back.

Brian Geswein

16Indeed, there is no perfect solution. A silent alarm is no better than the manometer, and I think we can all see issues with the audible alarm. At some point I think you have to put some of the responsibility of maintaining checking the system on the homeowner. I'm thinking more of this time being spent on alarms, etc. should be put into educating the general public. If they don't understand what the radon mitigation system is then no matter what you supply them with will not matter. Personally, I think the manometer, as all manufactures produce them, are one of the most misunderstood pieces of the radon mitigation system. Most say "system monitor" on them, and then there are numbers 1-4 printed on it. To many, outside the radon industry, that little devise is showing radon "level". I know the label right next to it says it is not radon level. BUT, who reads labels! All much of the general public know about radon is it should be under 4, (In the US) and this little "monitor" clearly shows the "level" is below 4. ALL IS GOOD!! I think the word monitor should be removed as well as the numbers. Leave only the lines as they are. When I brought this up to a major manufacturer a few years ago they said the numbers where there for mitigators to know the pressure. In my opinion any competent mitigator could figure that out without having the number printed on it. The only way to determine if a radon system is "working" is to test. There are many "running" systems out there that are not working. I know some mitigators leave monitors for homeowners to use. That is fine until the homeowner moves and takes it with them, or lends it to someone else to use and it never comes back.

Sorry this has gotten long. I just think we are trying to make it too complicated. I don't know the solution, but keep as simple as possible. More to educating the general public on testing in my opinion and not into more strict standards and requirements. All the new standards/requirements that get added keeps making it harder and harder on the small one man operations such as me.

To everyone who is on is or has been on any standards committee, board, or in any leadership role at all, please know this is not a complaint against any of you. I appreciate the time all of you have given. I just ask that we back up and take a look. Please don't make it more complicated. Testing is where it's at. Not trying to make a one size fits all situation. There is no such thing.

Thanks for listening to a small 175 +or- system/year contractor that's been around for 15 years trying to keep up. -

Bill Brodhead

44Thanks everyone for relaying all these real life situations with long term system maintenance. It is clarifying the issues that I will present to the committee. I can completely understand the issues with audible alarms. Fortunately there are new alarms coming to the market. One manufacturer I recently spoke with is scheduled to have a plug in and a separate battery alarm in January that can be programed by the installer to have light and sound or just light. So there will be several choices for installers. The issue with homeowners not able to understand what the u-tube is or realize his fan is dead is very real. Homeowners we called to replace a dead fan often had no idea where the fan was. As an industry we need to address this. A blinking red light plus the u-tube may be the best option for a typical homeowner.

Bill Brodhead

44Thanks everyone for relaying all these real life situations with long term system maintenance. It is clarifying the issues that I will present to the committee. I can completely understand the issues with audible alarms. Fortunately there are new alarms coming to the market. One manufacturer I recently spoke with is scheduled to have a plug in and a separate battery alarm in January that can be programed by the installer to have light and sound or just light. So there will be several choices for installers. The issue with homeowners not able to understand what the u-tube is or realize his fan is dead is very real. Homeowners we called to replace a dead fan often had no idea where the fan was. As an industry we need to address this. A blinking red light plus the u-tube may be the best option for a typical homeowner.

I assume that the battery alarm would be easier to install and thus a 1st choice for mitigators. However in reviewing the specifications for one model it listed the battery life as only 48 hours when the alarm was activated. This does not bode well for long term system operation. The standards committee should definitely consider these issues again.

I would also like to point out to this group that the different standard committee conference calls to review multiple issues are often 2 hours long with as many as 15 people on the call and literally calls are sometimes scheduled every 2 weeks. This is an incredible donation of time and effort to advance the quality of our entire industry. Committee members donation of their time needs to be recognized.

One last request.

I'm working on a research paper investigating ground based radon system exhaust dispersion and re-entrainment. If any of our good Canadian neighbors or US mitigators has had a radon system that appeared to re-entrain radon back into the house I would love to know the details. My direct email is wmbrodheadatgmaildotcom -

Andrew Costigan

34I definitely appreciate the donation of time the standards committee gives to the industry. And I have applied to be on the committee (still haven’t heard back yet). I also encourage others to apply - especially radon mitigation contractors. We all have real world experience that deserves to be shared and contributed.

Andrew Costigan

34I definitely appreciate the donation of time the standards committee gives to the industry. And I have applied to be on the committee (still haven’t heard back yet). I also encourage others to apply - especially radon mitigation contractors. We all have real world experience that deserves to be shared and contributed. -

Andrew Costigan

34Bill - one more thing to think about and take to the committee.

Andrew Costigan

34Bill - one more thing to think about and take to the committee.

How about systems that are horizontally cored into the foundation wall from outside the home or building? We only do a few of these a year - but in other parts of the country they do system installation like this frequently. This creates an outside only condition to place an alarm. The water proof tackle box method or the outdoor 6x6 or 4x4 junction box is an option to help keep it out of the elements. But not the temperatures.

Outdoor installations on these alarms voids the warranty. -

Wally Dorsey Jr

33How about a terrarium or aquarium type heater? Or a heater similar to that which I use to heat my chickens water in the winter. It's not really about heating so much, as it is about raising the temperature enough to keep the fluid from freezing. Of course that involves more cost of running electrical or a solar/battery combination... once again, thank you chickens, similar to the automated solar powered chicken I've installed on my hen houses. It could even be temperature sensitive.

Wally Dorsey Jr

33How about a terrarium or aquarium type heater? Or a heater similar to that which I use to heat my chickens water in the winter. It's not really about heating so much, as it is about raising the temperature enough to keep the fluid from freezing. Of course that involves more cost of running electrical or a solar/battery combination... once again, thank you chickens, similar to the automated solar powered chicken I've installed on my hen houses. It could even be temperature sensitive. -

Bill Brodhead

44100% outdoor piping and fan does present a problem and this would certainly be an issue with the alarm requirement. What we have done as a company is the following. For all commercial jobs and schools or in developments where there is a maintenance staff that must monitor the fans we always install the weatherproof 6X6 box with a magnehelic gauge outside. These types of installations typically include a fan cover both for appearance, protection from tampering and reduction in fan noise. The gauge gets installed above the cover and the vacuum tubing has minimal exposure to sunlight degradation. The material cost for this gauge is $100 but is easily included in the system cost when it is explained to the client the ease of checking the system operation from the outside. And it is a professional looking installation.

Bill Brodhead

44100% outdoor piping and fan does present a problem and this would certainly be an issue with the alarm requirement. What we have done as a company is the following. For all commercial jobs and schools or in developments where there is a maintenance staff that must monitor the fans we always install the weatherproof 6X6 box with a magnehelic gauge outside. These types of installations typically include a fan cover both for appearance, protection from tampering and reduction in fan noise. The gauge gets installed above the cover and the vacuum tubing has minimal exposure to sunlight degradation. The material cost for this gauge is $100 but is easily included in the system cost when it is explained to the client the ease of checking the system operation from the outside. And it is a professional looking installation.

For typical residential installations our company like others has to be competitive. We however never install a u-tube outside. I do not agree with manufacturers selling outdoor accessories that implying a u-tube can be installed outside. All U-tube oil in sunlight changes to clear color and is very difficult to read plus bugs and water. Our alternative has been to install the u-tube and label inside on the drywall and route tubing to the outside piping below the fan. Obviously you have to consult with the owner where this is acceptable. This typically means we are deciding on the fan location based on where the u-tube can be acceptably installed indoors. With slab on grade systems you typically have lots of latitude as to where the actual suction hole can be installed.

For the alarm requirement the same design would need to be done that routes tubing from outside piping to the inside alarm and then split to the u-tube. We purchased black tubing for the outside because it is more sunlight resistant. Inside we transition to clear tubing for appearance.

I hope this helps. -

Wally Dorsey Jr

33Bill,

Wally Dorsey Jr

33Bill,

As always, you're a font of well thought out and consistently innovative thinking. You're a credit to to our avocation, both in your ingenuity and your willingness to share your hard earned knowledge. We're lucky to have you amongst us as a human being and a fellow radon innovator. -

Andrew Costigan

34

Andrew Costigan

34

Here is a great example of what Bill is describing on a system done by David Smith on a school. -

Bob Wood

95So i said i would post what we are using as a self regulating heating cable on our commercial VOC systems here it is from amazon.ca

Bob Wood

95So i said i would post what we are using as a self regulating heating cable on our commercial VOC systems here it is from amazon.ca

https://www.amazon.ca/regulating-Industrial-Drawings-Available-Temperature/dp/B07VW6HKN1/ref=sr_1_5?crid=8KQ1QTVJ007Q&dchild=1&keywords=self+regulating+heat+trace&qid=1608583282&sprefix=self+regulating%2Caps%2C226&sr=8-5

We added a plug that would shut down power at above 50 degrees F.

https://www.amazon.ca/Frost-King-099000-Self-Regulating-Thermostat/dp/B0182HW816/ref=sr_1_20?crid=8KQ1QTVJ007Q&dchild=1&keywords=self+regulating+heat+trace&qid=1608583282&sprefix=self+regulating%2Caps%2C226&sr=8-20????

We just wrapped the flat cable up the pipe and covered with a black EPDM 1/2 inch thick insulation (it is waterproof) and covered it all with a white pvc pipe jacketing sealed the joints looks good and my client and engineer was happy. -

Bill Brodhead

44These are the outdoor magnehelics if no one has seen them before.

Bill Brodhead

44These are the outdoor magnehelics if no one has seen them before.

Radonaway sells the larger for about $78 plus you need the box and tubing. The other is a smaller mini-helic. Obar Systems in NJ sells this one for about $50 but it includes the mounting box and the tubing.

Remember that any clear or white tubing will degrade in sunlight. You need to use black tubing outdoors. The minihelic includes black tubing with the package.

Attachment

Attachment Fulll Mag $78

(1K)

Fulll Mag $78

(1K)

-

Robert Burns

31The larger one looks perfect. Right now I found UV protected tackle boxes for around $20. This issue only comes up for me with horizontally drilled systems on the outside. I have run PVC conduit with tubing in it down the wall to a place where we could go into a house and mount a manometer. It is rare to have that option.

Robert Burns

31The larger one looks perfect. Right now I found UV protected tackle boxes for around $20. This issue only comes up for me with horizontally drilled systems on the outside. I have run PVC conduit with tubing in it down the wall to a place where we could go into a house and mount a manometer. It is rare to have that option.

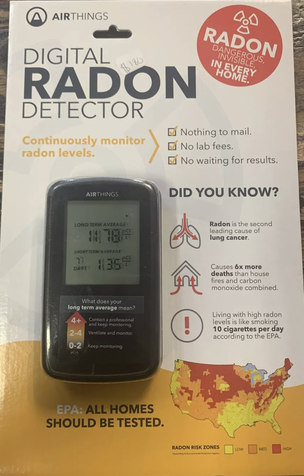

I can see a time in the future when a CRM, mounted on a basement wall, is almost as common as smoke detectors. It may be helpful for the standards committee to think about guidelines for a CRM that serves as the system monitor. Accuracy, audible alarm with a delay, 5 year warrenty, ac power + battery backup, reasonable cost for factory recalibration or exchange.

This would address the the issues of outside systems, false alarms, testing radon every two years and would give homeowners a clear understanding of what the monitor is telling them. I have homeowners that think that as long as the red fluid is below 4 they are fine.

As CRMs come down in cost they are becoming more attractive for this solution. -

Andrew Costigan

34I agree Robert - these highly accurate low cost CRM’s for homeowners are becoming very common and the cost is dropping on them every year. I am starting to see some in the $70 dollar range now.

Andrew Costigan

34I agree Robert - these highly accurate low cost CRM’s for homeowners are becoming very common and the cost is dropping on them every year. I am starting to see some in the $70 dollar range now.

Makes no sense to try and reinvent the wheel and force mitigators to come up with creative solutions to implement an active alarm / notification that has been prematurely required; when homeowners still have trouble with the simple U-tube device. We actually get our share of calls just on the manometer - let alone a battery powered alarms with a 1 year warranty.

I urge the committee to please let a few more years go by and then circle back and revisit this topic and see where the manufacturers are at with viable products or maybe we go a different direction entirely like the CRM’s. It’s really not fair to us what is happening now. MN the first state to actually legally enforce the requirement is becoming a test bed for these active notification devices at our business’s expense. -

Doug Kladder

12This has been an interesting discussion as it falls into the category of questioning one’s assumptions and focusing on intent rather than habit.

Doug Kladder

12This has been an interesting discussion as it falls into the category of questioning one’s assumptions and focusing on intent rather than habit.

Coming from the chemical processing industry it was always best to measure the variable one is attempting to control rather than a surrogate. In our case we are trying to control radon/RDPs. In the early years of this industry, radon monitoring equipment was expensive and did not provide a cost-effective means for direct monitoring of the key variable-radon. Hence a surrogate measurement of pressure was used. As many have pointed out in this thread “things have changed” and direct radon measurement has become more cost-effective. Furthermore, the use of consumer monitors will likely point out subtle deterioration of system performance more readily than a U-tube will.

The last point is made based upon experience of our students who began calling when homeowners acquired consumer CRMs that were showing elevated radon levels after a system had been installed previously and validated with a short-term test. After retesting with an approved short-term test device, the houses were indeed above 4 pCi/L even though the U-tube still showed the same vacuum. The logical explanation was that the original mitigation system likely never did fully reduce the levels but post-mitigation testing was faulty due to home seller non-compliance of testing protocols or testing during low radon entry periods.

Regarding 100% outdoor systems, this situation presents itself in the Rocky Mountain West as there are many homes where the drain tile is outside of the house and there is no internal sump to connect to. This is common with hillside houses where gravity allows surface water to drain down the hill without the need for a pump. Also, the lower levels of the home are walk-out and fully finished, therefore making a floor core a rather unsightly conversation piece. Hence, many systems are installed completely outside of the house and connected to the exterior perimeter drain. This presents a problem with pressure monitoring style performance indicators due to condensation in the connecting tubes. This can be solved in at least three ways:

1. Diaphragm repeaters that preclude moisture from the gauge (more costly and not too practical)

2. Ammeter style indicator on power to fan. This technique is incorporated into the low voltage systems manufactured by PDS. The current flow is proportional to the air flow in the system and the current can be used as a surrogate provided the meter face is redesigned like a “idiot gauge” on a car. This is especially workable on the secondary leg of the transformer.

3. Measure the radon inside of the house with a consumer grade CRM as an indicator, with an elevated reading being the impetus for verified measurement.

I trust that as the standards committee evolves that it will expand the allowance of methods that address the intent of a standard such that innovation can occur from both the practitioner as well as the innovator/scientist/engineer.

Doug Kladder

Colorado Vintage Co. -

Andrew Costigan

34Radon fan manufacturers warranty - 5 years

Andrew Costigan

34Radon fan manufacturers warranty - 5 years

Active notification device /

System alarm manufacturers warranty - 1 year

What am I missing here? -

Bill Brodhead

44From a point of view of reducing long term exposure which is what we are about, the inexpensive CRMs are truthfully the best choice as Doug has pointed out but that brings up the issue with long term reliability. Will these crms still be reasonably good indicators of elevated radon in 10 years? I have seen lots of u-tubes become stuck in their setting from dirt or bugs after 10 or 15 years but in general they do ok. The newest crms are only cell phone accessed so when the house gets sold there goes the crm. We would certainly consider the option of a crm that has a display that is permanently attached to a radon system. The issues with longevity with both alarms and crms does need to be considered.

Bill Brodhead

44From a point of view of reducing long term exposure which is what we are about, the inexpensive CRMs are truthfully the best choice as Doug has pointed out but that brings up the issue with long term reliability. Will these crms still be reasonably good indicators of elevated radon in 10 years? I have seen lots of u-tubes become stuck in their setting from dirt or bugs after 10 or 15 years but in general they do ok. The newest crms are only cell phone accessed so when the house gets sold there goes the crm. We would certainly consider the option of a crm that has a display that is permanently attached to a radon system. The issues with longevity with both alarms and crms does need to be considered.

Question: Has anyone had experience with homeowner crms drifting higher or lower over the years. I would assume the radon levels are low enough that their background counts don't grow significantly but I dont know that. -

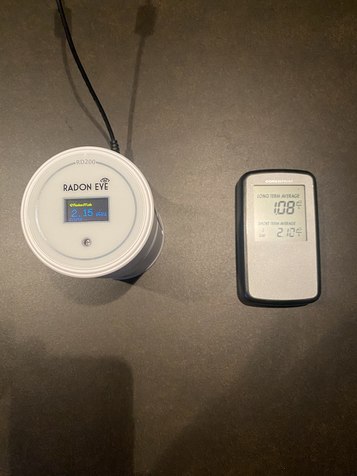

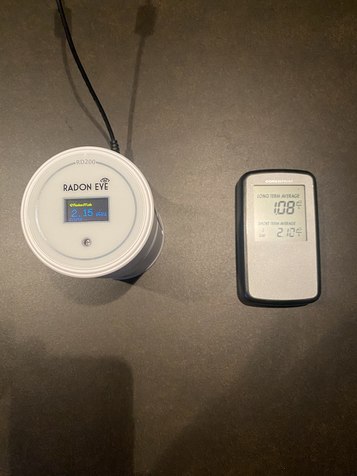

Andrew Costigan

34Bill I have both the radon eye and airthings corentium down in my basement - they have been down there for many years side by side and they are both right in line with one another. Every once in a while a cross check them with one of my Sun Nuclear or Femto tech crm’s and they are always spot on.

Andrew Costigan

34Bill I have both the radon eye and airthings corentium down in my basement - they have been down there for many years side by side and they are both right in line with one another. Every once in a while a cross check them with one of my Sun Nuclear or Femto tech crm’s and they are always spot on.

The nice thing about the airthings device is they have a holster that will screw right to the vent pipe for interior installations. For 100% exterior systems it can be fixed to the wall in a location approved by the homeowner. We also have many many customers with these devices and I can assure you if anything looked off we would be getting a phone call. Not one yet... -

Randy Weestrand

32This interesting conversation has focused on the pros and cons of techniques for announcing fan failure and system failure without fan failure. I look forward to hearing more, and identifying new “best practices”.

Randy Weestrand

32This interesting conversation has focused on the pros and cons of techniques for announcing fan failure and system failure without fan failure. I look forward to hearing more, and identifying new “best practices”.

But the issue at hand of ANSI / AARST standards requires answering a prerequisite question: how are “should”, “shall” and “best practice” to be used in the standards.

Our standards should use “shall” to identify minimum acceptable practices regarding things like pipe slope, manometers and labels. As entrepreneurs in a free market, many of us will exceed the minimum and brand ourselves as “better than the other guys”.

But the all-important “shall” can become an Orwellian bludgeon when a governing agency interferes with the market and demands the sale and purchase of a product that neither producers nor consumers want. I think “shall” does belong in the rules regarding producers installing seat belts in cars and smoke detectors in new homes. Does it belong in the rules regarding system alarms? I vote an emphatic “”NO”. Identify alarms as a “should” or a “best practice”. -

Andrew Costigan

34Wow! Well said Randy!

Andrew Costigan

34Wow! Well said Randy!

A simple “should” before the “shall” would have prevented all of the disagreements happening right now and would have given a chance for “us” the mitigators to see what works and what doesn’t for active notification. -

Robert Mahoney

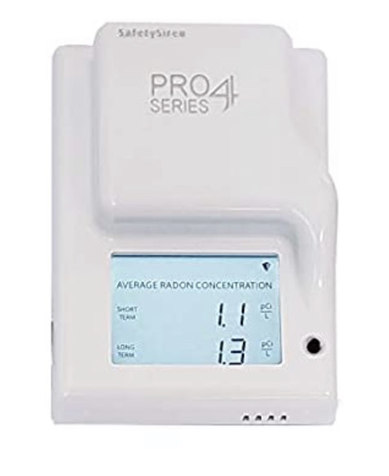

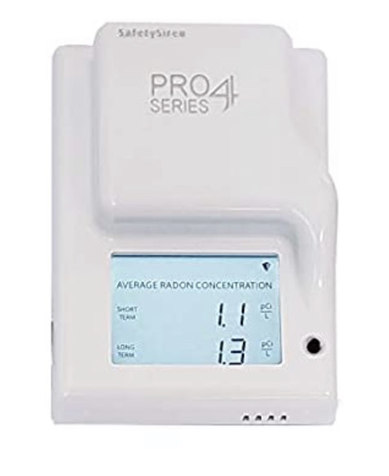

44Bill, with respect to your question about CRM’s, Bob Wood and myself used to recommend safety siren Pro 3’s as they were the only thing available.

Robert Mahoney

44Bill, with respect to your question about CRM’s, Bob Wood and myself used to recommend safety siren Pro 3’s as they were the only thing available.

However most have failed high, within 5-6 years, some as little as 3 years. -

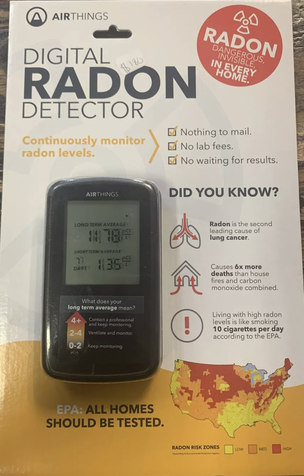

Andrew Costigan

34We have seen the same over the years with the safety siren pro 3’s - at about year 5 they start to get squirrelly. They do have a new one out now called the safety siren pro 4 - I have yet to see one though in person.

Andrew Costigan

34We have seen the same over the years with the safety siren pro 3’s - at about year 5 they start to get squirrelly. They do have a new one out now called the safety siren pro 4 - I have yet to see one though in person.

-

Marcel Brascoupe

9Up here in Canada, up until a few years ago, I used to supply a Safety Siren Pro Series 3 unit to the homeowners with every radon mitigation installation I had completed.... noticed after a few years like Rob and Bob mentioned up above, that I was getting calls from the homeowners about high readings.... in most cases, it was relating to power outages and power surges when the power came back on.... since the units were plugged into the wall with a power supply, the would get spiked when the power came back on and the average radon levels on the unit would suddenly spike up really high... in the beginning, I used to go investigate each case and even put in additional monitors to make sure the mitigation system was working well and in all cases, found that the Safety Siren was the culprit.... so would do a reset to the unit and everything went back to normal.... after several situations like this, when I would get a similar call from a client, I would simply ask them if they had experienced a power outage in their neighborhood over the last week or two and the majority of them confirmed with a yes, so I would simply tell them to reset the unit and if the levels were still showing high after the reset, then I would go out and investigate.... never had a call back yet from the clients after they reset the unit.... I guess one of the things to look out for when a radon monitor has a power supply and is plugged in a wall plug...

Marcel Brascoupe

9Up here in Canada, up until a few years ago, I used to supply a Safety Siren Pro Series 3 unit to the homeowners with every radon mitigation installation I had completed.... noticed after a few years like Rob and Bob mentioned up above, that I was getting calls from the homeowners about high readings.... in most cases, it was relating to power outages and power surges when the power came back on.... since the units were plugged into the wall with a power supply, the would get spiked when the power came back on and the average radon levels on the unit would suddenly spike up really high... in the beginning, I used to go investigate each case and even put in additional monitors to make sure the mitigation system was working well and in all cases, found that the Safety Siren was the culprit.... so would do a reset to the unit and everything went back to normal.... after several situations like this, when I would get a similar call from a client, I would simply ask them if they had experienced a power outage in their neighborhood over the last week or two and the majority of them confirmed with a yes, so I would simply tell them to reset the unit and if the levels were still showing high after the reset, then I would go out and investigate.... never had a call back yet from the clients after they reset the unit.... I guess one of the things to look out for when a radon monitor has a power supply and is plugged in a wall plug... -

Rich Whisler

3Thanks to everyone for the exchange of Ideas here. Special thanks to those that volunteer their time to work on improving our industry.

Rich Whisler

3Thanks to everyone for the exchange of Ideas here. Special thanks to those that volunteer their time to work on improving our industry.

Lots of different situations and workarounds by very dedicated and creative people. All methods have benefits and shortcomings. But in the end these issues have been discussed before, and the decision was made that nothing works like the EPA's recommendation to test every building every 2 years.

Things change in structures and in the ground under them. We should not be telling clients that these are forever solutions and that after installation they are "all good" unless there is an alarm of some type. I personally guarantee every client that the system will fail someday. Airflow, Internal alarms, U-tubes, consumer electronic CRMs, will all fail someday too.

I think the message needs to be on retests. Its the only reliable calibrated method that withstands all the scrutiny of the variety of situations we are discussing. AARST should focus on the message that these are mechanical systems that need to checked out for performance issues, and retesting needs to be conducted regularly. The installation is just the first step. Our industry installations, brochures, and interaction with the clients, needs to be refocused onto not only making, but also on keeping buildings safe from now on.

I can also share that we offer annual inspections (profitable) of installed systems to our clients which avoids system failures and re-exposure situations. We regularly find systems with sump pit covers off, external discharges redone by siding companies, home additions, new attic insulation, missing u-tubes, failing or dead fans, wetter sub slab conditions with reduced airflow, replacement windows, systems disabled by other contractors, and who knows what else I'll see next month. Airflow alarms won't catch most of these situations.

It can be done. I have reasonable success with getting clients to retest. Some have CRMs and they are more difficult to work with because they think the CRM is a substitute for our knowledge and experience, but we still have many that are cooperative.

I suggest that we continue to be the "EXPERTS" to our clients, and leverage our experience to their benefit. This is too important for us to be replaced by an alarm of any sort, that may identify some problems, but will also fail to identify other system problems.

Just my personal opinion. -

Carolyn Koke

3Thank you to Bruce Decker, Bill Brodhead and unnamed others for participating on and sharing your experiences about Standards committees. Discussions are detailed and occasionally emotionally charged. It is time-consuming, difficult and very important work.

Carolyn Koke

3Thank you to Bruce Decker, Bill Brodhead and unnamed others for participating on and sharing your experiences about Standards committees. Discussions are detailed and occasionally emotionally charged. It is time-consuming, difficult and very important work.

This thread on this Forum is an example of what Standards committee members can experience in any meeting. How do we notify the occupants of radon system operation? Does it need an alarm? What is an alarm? Is is audible? If not audible, do we call it an indicator? A warning? Can we imagine how such a device would be used or abused when installed? How might it affect overall radon system efficacy? What type of device is sufficient for the safety of the occupants? How many of these questions should be answered in the marketplace and not in the Standard?

So again, THANK YOU to those who participate on Standards committees.

I believe Standards must address public safety and health. We cannot have committees with a majority of mitigation contractors, or a majority representation of any one stakeholder group. All stakeholder interests must be represented per consensus standards process rules. There is important history and rationale for this methodology.

There are many examples of safety products now in use to which people originally objected. Anyone know the history of the seat belt? Today it is hard to imagine objection to seat belts, but there was loud and organized opposition to this now ubiquitous safety device.

Of those who object to the radon system alarm requirement, how many have statements on their websites that quote the US EPA's estimate of 21,000 deaths a year from radon-induced lung cancer? Radon is real and it can kill people. I know I could not tell any lung cancer victim or his/her loved ones that an alarm on a home improvement designed to help prevent a horrific illness is a bad idea. .

I have evacuated a hotel room because someone overcooked his egg sandwich in the breakfast area microwave. I have been awakened in the dead of night at home to deal with the dying battery in a chirping smoke or CO alarm. For me, the annoyance was outweighed by my preference for personal safety.

I am in favor of an alarm on radon systems. The manifestation of that concept in a product is a separate (and also important) discussion. There are any number of companies around the globe who will listen and address challenges such as this one. -

Andrew Costigan

34Carolyn - you failed to mention you work for the company that sells the only viable option and so you have a clear bias.

Andrew Costigan

34Carolyn - you failed to mention you work for the company that sells the only viable option and so you have a clear bias. -

Bill Brodhead

44Andrew. As much as would like to think we don't have a bias, we all have them. You certainly have a bias as a mitigator and I have one as an instructor. Carolyn's point about a diverse mix in a consensus group is the exact reason it is this way to balance out these bias positions. When you spend time on these committees we all learn that we need to make concessions to our bias and do our best to work out solution for the majority if not the entire group.

Bill Brodhead

44Andrew. As much as would like to think we don't have a bias, we all have them. You certainly have a bias as a mitigator and I have one as an instructor. Carolyn's point about a diverse mix in a consensus group is the exact reason it is this way to balance out these bias positions. When you spend time on these committees we all learn that we need to make concessions to our bias and do our best to work out solution for the majority if not the entire group. -

Andrew Costigan

34I completely understand what you are saying Bill regarding bias.

Andrew Costigan

34I completely understand what you are saying Bill regarding bias.

But when there is 90+% opposition by radon professionals and the committee passes it anyway.

That is a clear demonstration that the committee is out of touch with radon mitigation professionals and it is no longer a consensus standard. -

Bill Brodhead

44The committee works for hours addressing issues of bad systems or problems like dead fans that owners have no clue about. When a new standard requirement to address these issues is written it may take the manufacturers and installers some time to find the best solutions but to demand the rule be removed because your systems are not functioning for a week or a month is not convincing and certainly not acceptable for the rest of the entire country. The alternate of having a radon monitor if it could be permanently part of the system is a definite consideration. The other is to talk to manufacturers about what would work better. I have been consulting with a manufacturer who will have different alarms available this spring including a battery one with a 4 day delay and a silent button as well as a plug in alarm that has a built in digital gauge that replaces the utube. Obviously solutions like insulated pipe or alarms with digital pressure gauges add system cost. I always tried to market these extra costs as examples of how my company did higher quality work than my competitors either as standard equipment or customer options if they were upgrades.

Bill Brodhead

44The committee works for hours addressing issues of bad systems or problems like dead fans that owners have no clue about. When a new standard requirement to address these issues is written it may take the manufacturers and installers some time to find the best solutions but to demand the rule be removed because your systems are not functioning for a week or a month is not convincing and certainly not acceptable for the rest of the entire country. The alternate of having a radon monitor if it could be permanently part of the system is a definite consideration. The other is to talk to manufacturers about what would work better. I have been consulting with a manufacturer who will have different alarms available this spring including a battery one with a 4 day delay and a silent button as well as a plug in alarm that has a built in digital gauge that replaces the utube. Obviously solutions like insulated pipe or alarms with digital pressure gauges add system cost. I always tried to market these extra costs as examples of how my company did higher quality work than my competitors either as standard equipment or customer options if they were upgrades.

Welcome to the Radon ListServ!

Join Radon ListServ Categories that pique your interests and area of expertise.

More Discussions

- Terms of Service

- Useful Hints and Tips

- Sign In

- © 2026 Radon ListServ